Exploring the Versatility of Thermal Transfer Label Printers

Thermal transfer label printers have emerged as indispensable tools for businesses across various industries, offering unparalleled versatility in label printing applications.

From manufacturing and logistics to healthcare and retail, these printers provide a reliable solution for creating durable, high-quality labels that meet diverse needs.

In this blog, we dive into the multifaceted versatility of thermal transfer label printers, exploring their features, benefits, and wide-ranging applications.

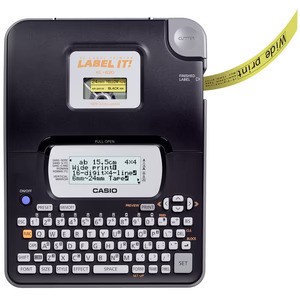

Introduction to Thermal Transfer Label Printers

A thermal transfer label printer utilizes heat to transfer ink from a ribbon onto label materials, creating crisp, long-lasting prints. Unlike direct thermal printing, which relies on heat-sensitive paper, thermal transfer printing offers superior durability and print quality.

This technology has become the preferred choice for industries requiring robust labeling solutions, thanks to its ability to withstand harsh environments and maintain legibility over time.

Diverse Label Material Compatibility

One of the key advantages of thermal transfer label printers is their compatibility with a wide range of label materials. Whether printing on paper, synthetic substrates, or specialty materials like polyester and polypropylene, thermal transfer printers deliver consistent results across various applications.

This versatility allows businesses to select the most suitable label material based on their specific requirements, ensuring optimal performance and durability.

High-Quality, Durable Prints

A thermal transfer label printer produces high-quality prints with exceptional clarity and resolution, ensuring readability and accuracy. The heat transfer process results in sharp, well-defined images and text, making labels easy to scan and interpret.

Unlike other printing methods, thermal transfer printing provides consistent print quality across various label sizes and materials, guaranteeing professional-looking results every time.

Variable Data Printing Capabilities

Thermal transfer label printers offer variable data printing capabilities, allowing businesses to customize labels with dynamic information. Whether printing serial numbers, expiration dates, or batch codes, organizations can incorporate unique data elements into each label to enhance traceability and compliance.

This flexibility is particularly valuable in industries such as pharmaceuticals, food and beverage, and electronics, where accurate labeling is essential for regulatory compliance and product safety.

Efficient Inventory Management

Thermal transfer label printers play a crucial role in efficient inventory management, enabling businesses to track and trace products throughout the supply chain. By printing barcode labels with unique identifiers, organizations can accurately monitor inventory levels, streamline order fulfillment processes, and prevent stockouts or overstock situations.

The ability to generate barcode labels on demand ensures that businesses have real-time visibility into their inventory levels and movement, enabling informed decision-making and optimized supply chain operations.

Enhanced Product Identification and Branding

Thermal transfer label printers enable businesses to create labels that not only convey essential product information but also enhance brand identity and recognition. With the ability to print logos, graphics, and branding elements, organizations can customize labels to reflect their unique brand aesthetic and messaging.

This branding consistency across product packaging and labeling helps build brand equity and fosters consumer trust and loyalty.

Additionally, thermal transfer technology supports the printing of variable data such as product descriptions, pricing information, and expiration dates, ensuring that labels provide comprehensive information to consumers.

Clear, well-designed labels enhance product identification and shelf visibility, making it easier for consumers to make informed purchasing decisions. By leveraging thermal transfer label printers to create visually appealing and informative labels, businesses can differentiate their products in competitive markets and drive sales growth.

Compliance with Regulatory Standards

Thermal transfer label printers enable businesses to comply with regulatory standards and industry requirements governing product labeling and traceability. In industries such as healthcare, pharmaceuticals, and food and beverage, accurate and compliant labeling is essential for ensuring product safety, quality, and integrity.

Thermal transfer technology facilitates the printing of regulatory information, warning labels, and usage instructions, helping businesses meet regulatory obligations and maintain consumer trust.

Moreover, thermal transfer labels support the printing of barcodes and other machine-readable codes required for track-and-trace initiatives and serialization mandates. By incorporating unique identifiers and data matrix codes into labels, organizations can track products throughout the supply chain, verify authenticity, and prevent counterfeiting or diversion.

Thermal transfer label printers provide businesses with the tools they need to adhere to regulatory standards and industry best practices, mitigating risks and protecting brand reputation.

Seamless Integration with Workflow Systems

Thermal transfer label printers seamlessly integrate with existing workflow systems and enterprise software solutions, enabling efficient label creation and management.

Many thermal transfer printers support standard communication protocols and connectivity options, such as Ethernet, USB, and wireless connectivity, facilitating integration with enterprise resource planning (ERP) systems, warehouse management software (WMS), and other business applications.

By connecting thermal transfer printers to centralized data repositories and workflow automation platforms, businesses can streamline label printing processes, reduce manual errors, and improve overall productivity.

Automated data synchronization ensures that labels contain accurate information, eliminating the risk of discrepancies or inconsistencies in labeling. Thermal transfer label printers empower organizations to optimize workflow efficiency, enhance data accuracy, and achieve greater operational agility in dynamic business environments.

Cost-Effectiveness and Return on Investment

While the initial investment in thermal transfer label printers and consumables may represent a significant upfront cost, the technology offers long-term cost-effectiveness and a favorable return on investment (ROI).

The durability and reliability of thermal transfer labels minimize the need for reprints and replacements, reducing material waste and operational downtime. Over time, the cost savings associated with lower maintenance requirements and improved efficiency justify the initial investment in thermal transfer printing solutions.

Moreover, thermal transfer label printers offer scalability and versatility, allowing businesses to adapt to changing labeling requirements and scale operations as needed. With the ability to accommodate various label sizes, materials, and printing specifications, thermal transfer printers provide a cost-effective solution for businesses of all sizes and industries.

By investing in thermal transfer technology, organizations can optimize their labeling processes, enhance operational efficiency, and drive business growth.

Endnotes

In conclusion, thermal transfer label printers offer unmatched versatility and functionality, empowering businesses to create high-quality, durable labels for a wide range of applications.

From manufacturing and logistics to healthcare and retail, thermal transfer technology provides the tools and capabilities needed to meet diverse labeling requirements and regulatory standards.

By leveraging the features and benefits of thermal transfer label printers, organizations can enhance productivity, streamline workflow processes, and achieve greater success in today’s competitive marketplace.