In the hustle and bustle of urban life, noise pollution can be a significant concern, affecting our well-being and productivity. Fortunately, sound damping sheets offer a promising solution for mitigating noise levels in various environments, from residential and commercial spaces to industrial settings. But just how effective are these sound damping sheets in reducing noise? In this article, we’ll look at the science of sound dampening technology, the elements that influence its performance, and how Polycrafts’ innovative rubber flooring solutions help to reduce noise in diverse applications.

What Are Sound Damping Sheets and How Do They Work?

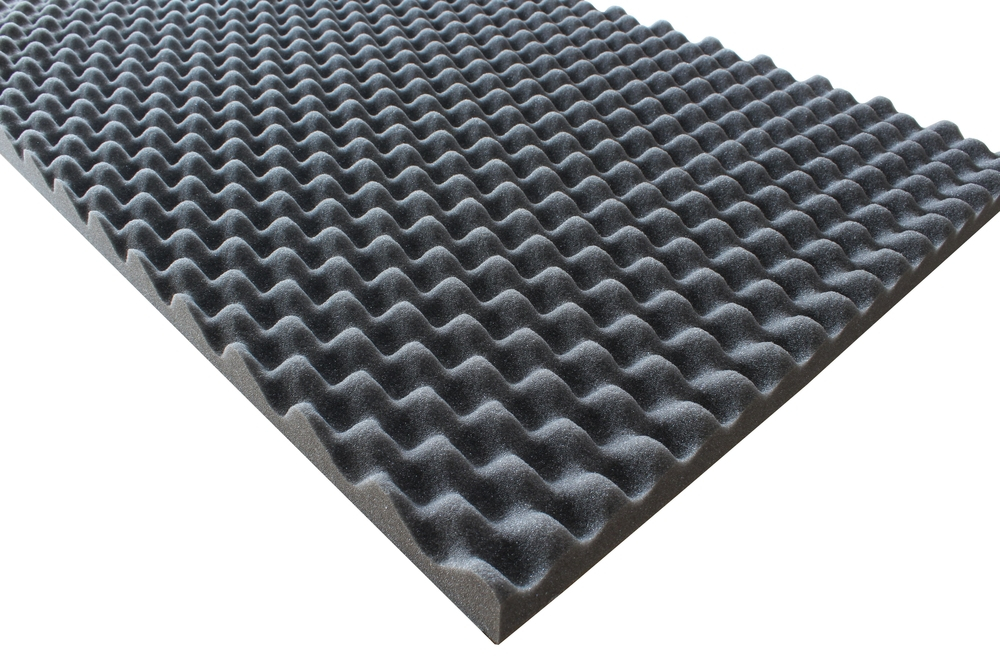

Sound damping sheets, also known as vibration damping sheets or automotive damping sheets, are flexible materials designed to reduce noise and vibration in various applications. Composed of viscoelastic materials such as rubber or polymer compounds, these sheets absorb and dissipate sound energy, effectively reducing the transmission of noise through solid surfaces. When installed on walls, floors, ceilings, or machinery panels, sound damping sheets convert sound waves into heat energy through internal friction, thereby minimizing noise levels and creating quieter environments.

How Do Sound Damping Sheets Reduce Noise Transmission?

Sound damping sheets function by addressing two primary mechanisms of noise transmission: airborne noise and structure-borne noise. Airborne noise occurs when sound waves travel through the air and impact solid surfaces, while structure-borne noise occurs when vibrations are transmitted through solid structures, such as walls, floors, or machinery. Sound damping sheets target both types of noise transmission by:

Absorbing Sound Energy:

The viscoelastic properties of sound damping sheets allow them to absorb sound energy and convert it into heat energy through internal friction. This process reduces the amplitude of sound waves, effectively dampening noise and preventing it from propagating through solid surfaces. By dissipating sound energy within the material, sound damping sheets help to mitigate the transmission of unwanted noise, resulting in quieter and more peaceful environments for occupants.

Decoupling Vibrating Surfaces:

By applying sound damping sheets to vibrating surfaces, such as metal panels or machinery enclosures, the sheets act as a barrier that decouples the vibrating surface from adjacent structures. This decoupling effect reduces the transmission of structure-borne noise, resulting in quieter and more comfortable environments. By isolating vibrating surfaces and preventing the transfer of vibrations to surrounding structures, sound damping sheets help to minimize noise pollution and create a more tranquil and enjoyable environment for occupants.

What Factors Influence the Effectiveness of Sound Damping Sheets?

Several factors influence the effectiveness of sound damping sheets in reducing noise, including:

- Material Composition: The composition of the sound damping material plays a crucial role in its effectiveness. High-quality viscoelastic materials with optimal density, thickness, and damping properties offer superior noise reduction performance.

- Thickness and Coverage Area: The thickness and coverage area of sound damping sheets determine their ability to absorb and dissipate sound energy. Thicker sheets and greater coverage area provide increased noise reduction benefits, especially in areas with high noise levels or vibration.

- Installation Method: Proper installation is essential for maximizing the effectiveness of sound damping sheets. Correct placement, alignment, and surface preparation ensure optimal contact between the damping material and the vibrating surface, enhancing noise reduction performance.

- Environmental Conditions: Environmental factors such as temperature, humidity, and exposure to moisture or chemicals can affect the durability and performance of sound damping sheets. Choosing materials with excellent weather resistance and chemical stability ensures long-term effectiveness in diverse operating conditions.

What Are the Applications of Sound Damping Sheets?

Sound damping sheets find a wide range of applications in various industries and environments, including:

- Automotive: Sound damping sheets are used in vehicle interiors to reduce road noise, engine noise, and vibration, enhancing passenger comfort and acoustic quality. By applying sound damping sheets to vehicle panels and surfaces, automotive manufacturers can create quieter and more enjoyable driving experiences for passengers, while also improving the overall quality of sound reproduction from in-car audio systems.

- Architectural: In architectural applications, sound damping sheets are installed in walls, ceilings, and floors to minimize noise transmission between rooms, floors, or building levels, creating quieter and more comfortable living and working spaces. By incorporating sound damping sheets into building designs, architects and designers can effectively control sound levels and create environments that promote productivity, concentration, and relaxation for occupants.

- Industrial: Industrial environments often experience high levels of noise and vibration from machinery, equipment, and manufacturing processes. Sound damping sheets are used to dampen noise and vibration in machinery enclosures, control rooms, and production facilities, improving worker safety and productivity. By reducing noise levels and vibrations, sound damping sheets help create safer and more comfortable working environments, reducing the risk of hearing damage and fatigue among workers.

- Commercial: Commercial spaces such as offices, retail stores, and entertainment venues employ sound damping sheets to create acoustically optimized environments with reduced reverberation and background noise levels. By installing sound damping sheets in ceilings, walls, and floors, commercial property owners and managers can enhance the comfort and enjoyment of customers and employees, while also improving the clarity of communication and the overall ambiance of the space.

How Does Polycrafts’ Rubber Flooring Contribute to Noise Reduction?

Polycrafts, a leading manufacturer of rubber flooring and sound damping solutions, offers a range of innovative products designed to enhance acoustic comfort and noise reduction in diverse applications. Our rubber flooring products incorporate advanced sound damping technology, providing effective noise reduction benefits while offering durability, aesthetics, and ease of maintenance. Whether used in residential, commercial, or industrial settings, Polycrafts’ rubber flooring solutions contribute to quieter, more comfortable environments, promoting well-being, productivity, and acoustic quality.

Conclusion: Harnessing the Power of Sound Damping Sheets for Noise Reduction

In conclusion, sound damping sheets are highly effective tools for reducing noise and vibration in various applications, offering benefits such as improved acoustic comfort, enhanced productivity, and increased safety. By understanding the science behind sound damping technology and considering factors such as material composition, installation method, and coverage area, users can maximize the effectiveness of sound damping sheets in creating quieter, more peaceful environments. With Polycrafts’ innovative rubber flooring solutions, customers can enjoy the benefits of superior noise reduction performance, durability, and aesthetics, ensuring optimal acoustic comfort and well-being in any environment.

Also, don’t forget to check out the other interesting articles on this website.