In the vast landscape of manufacturing, certain unsung heroes often go unnoticed. Among them are custom enclosure manufacturers ins, whose precision engineering and tailored solutions form the backbone of numerous industries. From protecting delicate electronics to housing critical machinery, these specialists play a pivotal role in ensuring functionality, safety, and efficiency across diverse sectors.

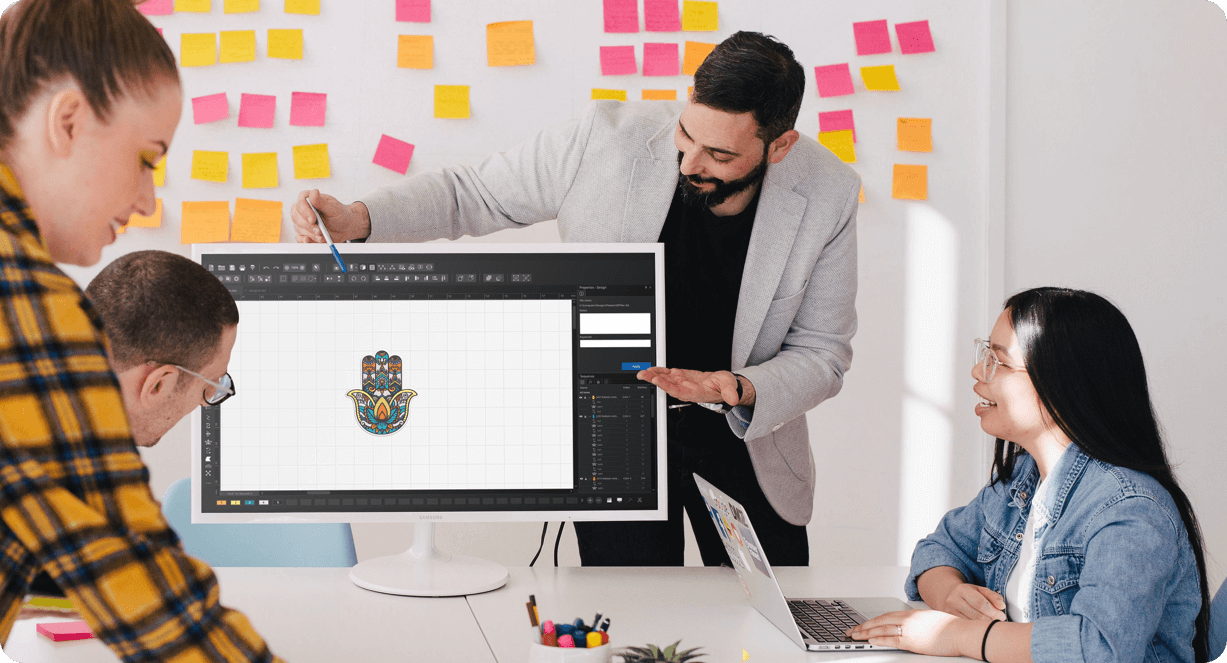

The Craftsmanship Behind Custom Enclosures

At the heart of custom enclosure manufacturing lies a blend of artistry and engineering. Unlike off-the-shelf solutions, custom enclosures are meticulously designed to meet specific requirements. Whether it’s a compact casing for sensitive medical equipment or a rugged enclosure for outdoor telecommunications gear, each project demands a unique approach.

Custom enclosure manufacturers start by understanding the client’s needs in detail. They delve into factors such as environmental conditions, regulatory standards, and space constraints. Armed with this knowledge, they embark on the design process, employing cutting-edge software and advanced techniques to craft solutions that marry form with function.

Tailored Solutions for Diverse Industries

The applications of custom enclosures span a wide spectrum of industries, each with its own set of challenges and specifications.

1. Electronics and Telecommunications

In an age dominated by technology, the need to safeguard electronic components from dust, moisture, and electromagnetic interference is paramount. Custom enclosure manufacturers excel in creating housings that provide optimal protection without compromising signal integrity or thermal management. From sleek cabinets for data centres to rugged enclosures for outdoor networking equipment, these specialists ensure that critical infrastructure remains secure and operational.

2. Healthcare and Biotechnology

Precision is non-negotiable in the realm of healthcare and biotechnology. Custom enclosures play a crucial role in safeguarding sensitive medical devices and laboratory equipment. Whether it’s MRI machines, PCR instruments, or incubators, these enclosures are designed to maintain sterile environments, minimize contamination risks, and adhere to stringent regulatory standards. Moreover, they are often tailored to integrate seamlessly with existing infrastructure, maximizing space efficiency and workflow productivity.

3. Aerospace and Defense

The aerospace and defence sectors demand ruggedness, reliability, and uncompromising performance. Custom enclosure manufacturers rise to the challenge by engineering solutions that withstand extreme temperatures, vibration, shock, and electromagnetic interference. Whether it’s avionics systems, military communications gear, or satellite payloads, these enclosures provide the resilience and security required for mission-critical operations.

4. Industrial Automation

In the era of Industry 4.0, automation is revolutionizing manufacturing processes. Custom enclosures serve as the guardians of automation infrastructure, housing PLCs, motor drives, sensors, and other control systems. Beyond protection, these enclosures are designed for seamless integration, modularity, and scalability, empowering factories to adapt to evolving production needs with ease.

Driving Innovation and Sustainability

In addition to meeting current needs, custom enclosure manufacturers are at the forefront of driving innovation and sustainability.

1. Material Science

With a growing emphasis on sustainability, manufacturers are exploring eco-friendly materials and manufacturing processes. Custom enclosure manufacturers are no exception, leveraging advanced materials such as recycled plastics, bio-based composites, and lightweight alloys. Not only do these materials reduce environmental impact, but they also offer enhanced performance characteristics such as durability, thermal conductivity, and electromagnetic shielding.

2. Additive Manufacturing

Additive manufacturing, or 3D printing, has emerged as a game-changer in the realm of custom enclosures. This technology enables manufacturers to create complex geometries with unprecedented speed and precision. Moreover, it facilitates on-demand production, eliminating the need for costly tooling and reducing waste. From prototyping to end-use parts, additive manufacturing is revolutionizing the way custom enclosures are designed and fabricated.

3. Smart Enclosures

As the Internet of Things (IoT) continues to proliferate, custom enclosures are evolving into smart, connected devices. Integrated sensors, actuators, and communication modules enable real-time monitoring, predictive maintenance, and remote diagnostics. By harnessing data analytics and machine learning, these smart enclosures optimize performance, minimize downtime, and prolong equipment lifespan.

Conclusion: The Invisible Guardians

In the grand tapestry of manufacturing, custom enclosure manufacturers may remain unseen, but their impact is unmistakable. Through meticulous craftsmanship, innovative solutions, and unwavering dedication, these specialists shape industries and enable progress. From protecting vital equipment to driving sustainability initiatives, custom enclosures are the unsung heroes that safeguard the world of manufacturing, one bespoke solution at a time.